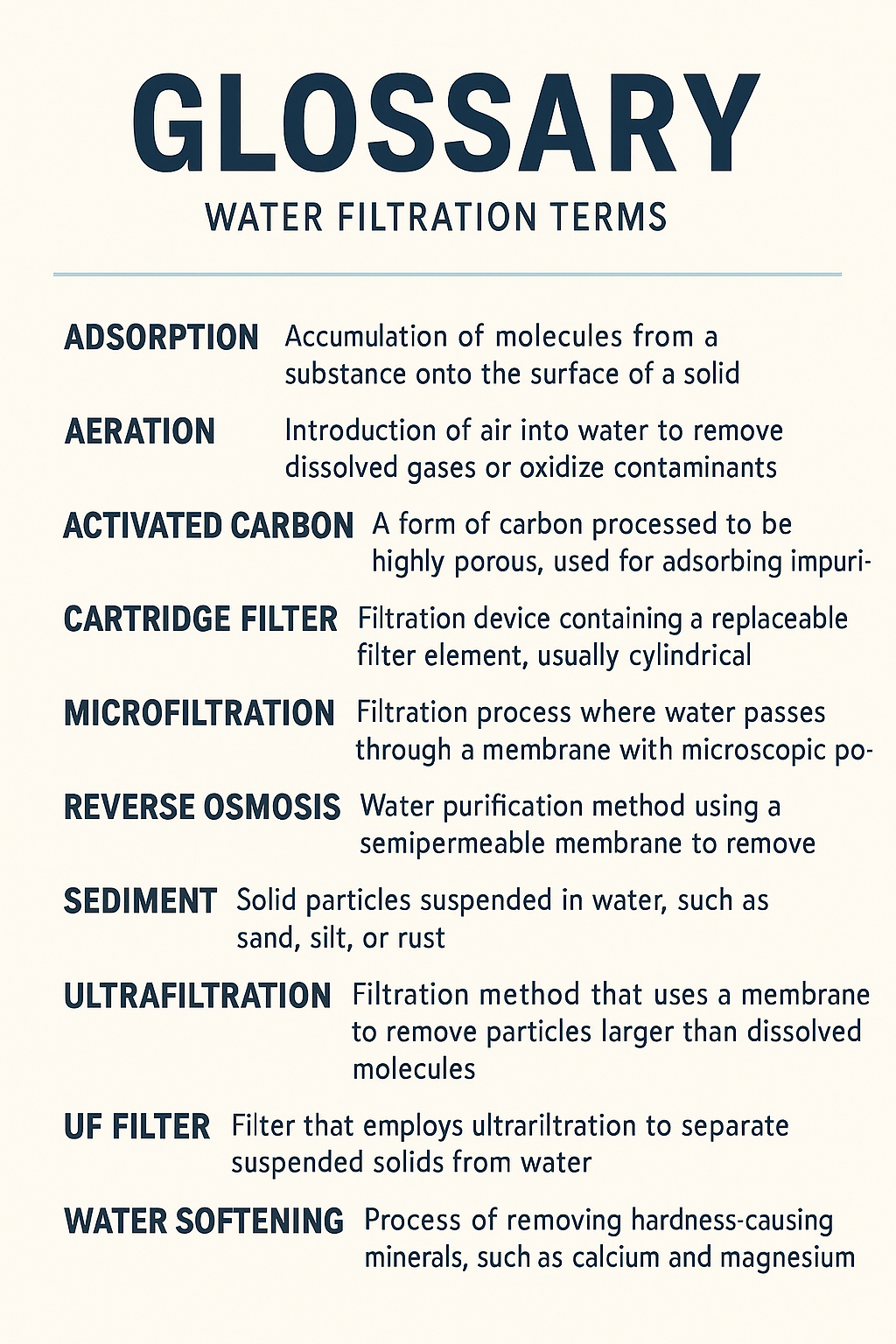

OEM Filter Design Glossary

This glossary is intended to smooth the OEM filter design process. It contains helpful definitions of key terms in preparation and support of a...

4 min read

Byron Druss : Sep 5, 2025 4:21:35 PM

Ultrapure lab water

(UPW) is like a lab's clean room, but in liquid form. At 18 MΩ-cm resistivity, Type I water isn't just "really clean"—it's so pure that microscopic contaminants you can't even see will mess up your results.

Yet, resistivity doesn't tell you everything. Your UPW might still contain organic nasties, endotoxins, and nucleases that sneak right past electrical measurements. That's why today's purification systems—also known as "polishers"—use several different technologies working together like a team.

Critical Applications Where UPW Makes the Difference

Analytical Chemistry:

Molecular Biology & Cell Culture:

Ultrapure Water Types Comparison

|

Property |

Type I |

Type II |

Type III |

Type IV |

|

Electrical conductivity, max (µS/cm at 25°C) |

0.0555 |

1.0 |

0.25 |

5.0 |

|

Electrical resistivity, min (MΩ·cm at 25°C) |

18 |

1.0 |

4.0 |

0.2 |

|

pH at 25°C |

* |

* |

* |

5.0 to 8.0 |

|

Total organic carbon (TOC), max (µg/L) |

50 |

50 |

200 |

No limit |

|

Sodium, max (µg/L) |

1 |

5 |

10 |

50 |

|

Chlorides, max (µg/L) |

1 |

5 |

10 |

50 |

|

Residual Chlorine, max (µg/L) |

50 |

50 |

50 |

|

|

Total silica, max (µg/L) |

3 |

3 |

500 |

No limit |

The measurement of pH in Type I, II, and III reagent waters has been eliminated from this specification because these grades of water do not contain constituents in sufficient quantity to significantly alter the pH.

What Happens When Your Water Goes Bad

Bad water quality is like having static on your radio—it messes up everything you're trying to hear. The problems start small and add up fast.

You'll notice right away:

Expensive long-term damage:

Understanding ASTM Standards

The ASTM D1193 standard breaks lab water down into four main types. Each type serves different needs.

Worth noting: The newer standards still include those Microbial Grades A, B, and C from earlier versions. These set specific limits for bacterial counts and endotoxin levels when you're doing work that's sensitive to microbes.

What’s Behind Ultra-Pure Water

Modern UPW systems layer different purification technologies like security checkpoints at an airport. Each one catches what the others might miss.

Dual-wavelength UV light at 185nm, reducing organic contaminants, and 254nm, which damages the DNA that bugs need to reproduce, so they can't multiply and cause infections.

Ultrafiltration is basically size-based screening. It removes particles and large molecules, and some filters are even charged to grab onto specific contaminants.

Mixed-bed ion exchange provides the final polish to get you to those ultra-low contamination levels.

Keeping Your Water System Happy

Once installed, monitoring and maintaining the system ensures it continues to delivery the level of reagent water required. Think of it like routine car maintenance where if you ignore it, you'll pay later.

Key watchlist: conductivity readings, TOC levels, bacterial counts, and endotoxin levels. And add these basic good lab practices like using proper filter tips and keeping work areas clean help prevent contamination from sneaking in.

The Bottom Line

Your lab results are only as good as the water you use to get them. The lab water system and its proper maintenance, like any other critical process, is a link in the chain in generating trustworthy data.

Investing in proper water purification and staying current with maintenance pays off with better accuracy, less downtime, and results you can trust. In today's competitive research world, cutting corners on water quality means much more expensive consequences later.

Frequently Asked Questions

Q1: How often should we test our ultrapure water quality?

It depends on how critical things are. Most labs do fine with daily conductivity checks and weekly comprehensive testing for TOC, bacteria, and endotoxins. If you're running high-volume work or super-sensitive assays, you might want continuous monitoring. Some systems have a TOC measuring capability built in. The main thing is catching problems before they ruin your experiments.

Q2: What's the real cost of poor water quality beyond obvious failures?

Beside the results having downstream consequences, there are many hidden costs: more frequent instrument maintenance, spending extra time developing methods, burning through more reagents on failed runs, and that nagging doubt about whether your results are trustworthy. Some studies suggest labs with water quality issues spend 15-20% more time chasing down "mysterious" problems that actually trace back to contaminated water.

Q3: Can we store ultrapure water, or must it be used immediately?

UPW is kind of like fresh fruit—it starts going bad the moment you bring it home. You can store it, but you need to be smart about it. Well-designed storage systems with recirculation, UV sterilization, and proper materials can keep water good for maybe 24-48 hours. But stuff can still leach from containers or bacteria can start growing. For critical work, point-of-use generation is still your best bet. Check out the article "How Fast Ultrapure Water Goes Bad in a Lab" if you want to see just how quickly resistivity drops in the first couple of hours and days.

Q4: How do we validate that our water system meets our specific application needs?

Just meeting ASTM specs on paper isn't enough—you need to prove the water actually works for what you're doing. Start with application-specific testing: run your trickiest assays with the water and compare to known good standards. The new ASTM D1193-24 standard actually gives you a structured approach with Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to make sure your system consistently delivers. Document your baseline performance, then keep monitoring to make sure water quality correlates with your analytical results.

Q5: What should we do when water quality suddenly drops below specifications?

When your water quality tanks, treat it like a contamination emergency. Stop using the water immediately because it will only make the problem worse. Check your consumables first since filters, resins, and UV lamps are usually the culprits. Look at what's changed recently—maintenance, environmental conditions, anything unusual. Document everything so you can spot patterns later. Most importantly, don't start using the water again until you've figured out what went wrong and fixed it. Taking a systematic approach prevents the same problem from happening again and keeps everyone confident in your results.

Q6: How can we get the latest ASTM D1193-24 standard?

You can buy the current standards directly from ASTM's website.

Remember, when your water quality fails, you're dealing with an emergency. Stop using the water right away to avoid messing up ongoing work. Check your consumables first—they're usually the easiest fix and the most reliable way to keep your ultrapure lab water system running right.

Discover the CLïR lab water system best suited for your application.

Want to learn more about the ins and outs of water treatment? Subscribe to this blog and we'll keep you posted.

This glossary is intended to smooth the OEM filter design process. It contains helpful definitions of key terms in preparation and support of a...

After interviewing Bailey Rau, Product Development and Manufacturing Engineer at ResinTech, about designing water filters we prioritize some...

If you're working with ion exchange resin filters, you've probably wrestled with the age-old question: should I go wider or longer? I've seen...

After interviewing Bailey Rau, Product Development and Manufacturing Engineer at ResinTech, about designing water filters we prioritize some...

If you're working with ion exchange resin filters, you've probably wrestled with the age-old question: should I go wider or longer? I've seen...

The Hidden Enemy in Your Chromatograms Ghost peaks are the analytical chemist's nightmare. They appear where they shouldn't. They make your data...