When Good Methods Go Bad: The Ghost Peak Problem Haunting Your LC-MS

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.

3 min read

Byron Druss : Updated on July 30, 2025

Your HPLC system is calibrated perfectly. Your columns are fresh. Your mobile phase is prepared with precision. Yet your results are inconsistent, your baselines are noisy, and mysterious peaks keep appearing in your chromatograms. The culprit might be hiding in plain sight: compromised ultrapure water (UPW).

Even with Type I water meeting the minimum 18 MΩ-cm resistivity standard, trace contaminants can wreak havoc on analytical chemistry workflows. These invisible enemies don't just affect one measurement—they cascade through your entire analytical process, creating problems that can take days to identify and weeks to resolve.

Baseline Noise: The Silent Signal Destroyer

Baseline noise turns your smooth chromatographic baseline into a chaotic mess of fluctuations. When organic contaminants lurk in your UPW, they create random background signals that interfere with your detector's ability to distinguish between true analyte peaks and noise. This means your instrument struggles to detect low-concentration samples, forcing you to increase injection volumes or extend run times. The practical impact hits immediately: you lose sensitivity for trace analysis, your method validation fails, and you spend hours troubleshooting what appears to be an instrument problem. In reality, microscopic organic compounds in your water are generating competing signals that mask your target analytes.

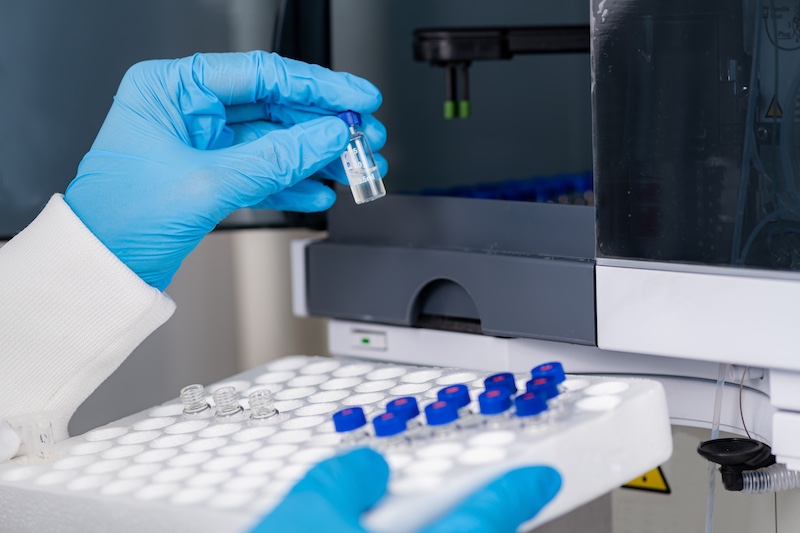

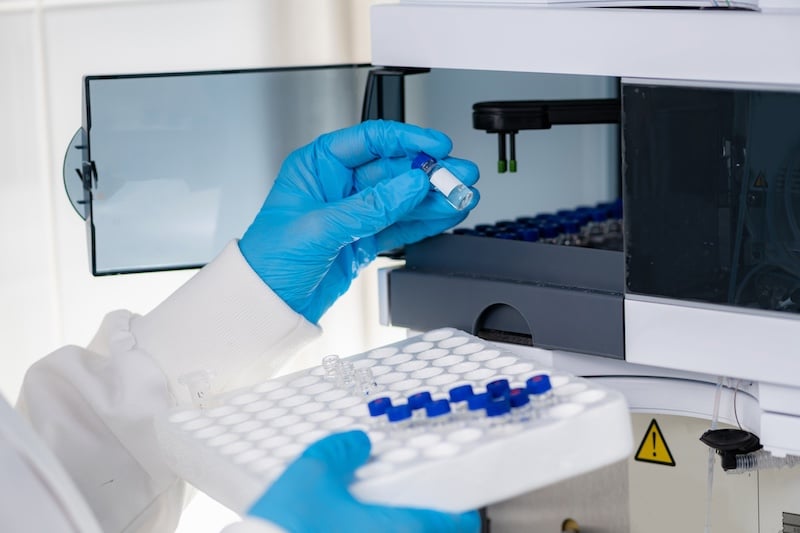

Ghost Peaks: The Phantom Signals

Ghost peaks appear like uninvited guests in your chromatogram, showing up at unexpected retention times and throwing off your entire analysis. These phantom signals originate from organic contaminants in your UPW that have similar chemical properties to your mobile phase components. When these contaminants concentrate during sample preparation or react with your analytical conditions, they create peaks that mimic real analytes. The result is devastating: you may report false positives, spend days trying to identify unknown compounds, or worse, make critical decisions based on data that includes phantom results. Your carefully validated methods become unreliable, and regulatory compliance becomes a nightmare.

Column Damage: The Expensive Consequence

Column damage from contaminated UPW is like death by a thousand cuts. Inorganic ions, bacteria, and particulates gradually accumulate in your column's packing material, changing its selectivity and reducing its lifespan. Metal ions can catalyze unwanted reactions with your stationary phase, while bacteria form biofilms that create pressure buildup and irregular flow patterns. The financial impact is immediate and ongoing: columns that should last months fail within weeks, back-pressure increases forcing system shutdowns, and peak shapes deteriorate beyond acceptable limits. You're not just replacing expensive columns more frequently—you're losing productivity every time you have to re-equilibrate systems and re-validate methods.

Poor Reproducibility: The Credibility Killer

Poor reproducibility destroys the foundation of analytical chemistry: the ability to generate consistent, reliable results. When your UPW contains variable levels of contaminants, your analytical performance becomes unpredictable. One day your method works perfectly, the next day your recovery rates are off by 20%. This inconsistency stems from fluctuating contaminant levels that interfere differently with each analysis. The consequences extend far beyond individual measurements: your method validation fails statistical requirements, regulatory audits become problematic, and your lab's reputation for reliable data suffers. Clients lose confidence, research conclusions become questionable, and your team spends more time investigating "mysterious" method failures than generating results.

The Path Forward

These four problems represent just the tip of the iceberg when it comes to UPW contamination in analytical chemistry. Each issue creates a cascade of downstream effects that can paralyze even the most well-equipped laboratories. The solution isn't just about meeting basic water specifications—it's about understanding how different contaminants interact with your specific analytical methods and implementing monitoring strategies that prevent problems before they occur.

In upcoming articles, we'll dive deeper into each of these challenges, exploring the specific contaminants responsible, detection strategies, and prevention methods that keep your analytical chemistry workflows running smoothly. We'll also examine real-world case studies where proper UPW management transformed struggling analytical programs into reliable, high-throughput operations.

Frequently Asked Questions

Q1: How can I tell if my UPW is causing analytical problems versus instrument issues?

Start with a systematic approach: run your most sensitive method with freshly prepared UPW from different sources or at different times. If problems persist regardless of water source, focus on instrument maintenance. If issues correlate with specific water batches or preparation times, investigate your purification system. Document baseline performance with known-good water to establish comparison standards.

Q2: What's the most critical UPW parameter to monitor for analytical chemistry applications?

While resistivity gets the most attention, Total Organic Carbon (TOC) is often more critical for analytical chemistry. Organic contaminants directly interfere with most analytical methods, creating the exact problems described above. Monitor TOC levels continuously and establish alert thresholds based on your most sensitive applications—typically well below the 50 µg/L Type I specification.

Q3: Can I use stored UPW for analytical chemistry, or must it be freshly prepared?

Fresh is always better, but properly stored UPW can work for less sensitive applications. The key is understanding degradation patterns: organic contaminants can leach from storage containers, bacterial growth can occur in stagnant systems, and dissolved gases can change solution chemistry. If you must store UPW, use inert containers, maintain circulation, and monitor quality parameters before each use.

Q4: How do I validate that my UPW meets my specific analytical method requirements?

Method-specific validation goes beyond standard specifications. Run your most challenging samples (lowest concentrations, most complex matrices) with your UPW and compare performance to reference standards. Establish method-specific acceptance criteria for baseline noise, peak resolution, and reproducibility. Document these requirements and use them to set water quality alert levels that prevent problems before they impact results.

Q5: What should I do when I suspect UPW contamination is affecting my results?

Stop using suspect water immediately to prevent further damage. Document the problem thoroughly, including chromatograms, system performance data, and timing correlations. Switch to a known-good water source if available, or implement immediate purification system maintenance. Most importantly, assess which recent analyses might be affected and determine whether retesting is necessary before releasing results.

Discover the CLïR lab water system best suited for your application.

Want to learn more about the ins and outs of water treatment? Subscribe to this blog and we'll keep you posted.

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.

Your HPLC columns shouldn't fail after a few weeks. Under normal operating conditions, most reverse-phased C18 columns deliver stable performance for...

Ultrapure water (UPW) is like a lab's clean room, but in liquid form. At 18 MΩ-cm resistivity, Type I water isn't just "really clean"—it's so pure...

Your LC-MS system is calibrated perfectly between your set up and check standards. Your columns are fresh. You are running validated methods. Yet...

Your HPLC columns shouldn't fail after a few weeks. Under normal operating conditions, most reverse-phased C18 columns deliver stable performance for...

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.