When Good Methods Go Bad: The Ghost Peak Problem Haunting Your LC-MS

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.

3 min read

Byron Druss : Updated on September 15, 2025

The Hidden Enemy in Your Chromatograms

Ghost peaks are the analytical chemist's nightmare. They appear where they shouldn't. They make your data unreliable and your methods invalid.

The impact is immediate and costly: Failed method validations. Delayed product releases. Regulatory compliance issues. Lost revenue from rejected batches.

What Creates These Phantom Signals

Ghost peaks emerge from trace contaminants in your water supply. These contaminants concentrate during sample preparation. They interfere with ionization. They create false positive signals.

The problem compounds over time. Each analytical run deposits more contaminants. Your system becomes increasingly contaminated. Your baseline noise increases. Your detection limits suffer.

HPLC: Where Water Quality Makes or Breaks Separation

The Contamination Cascade

Regular lab water contains dissolved organics. These organics elute at unpredictable times. They create peaks that mimic your target compounds. Your integration software can't distinguish between real signals and artifacts.

Technical mechanism: Trace organics from municipal water treatment accumulate in your mobile phase. UV-absorbing compounds like chlorinated organics appear as broad, tailing peaks. Humic substances create baseline drift that masks low-level analytes.

Real-world impact: Your method precision degrades. Quantitation becomes unreliable. Method transfer between labs fails. Regulatory submissions are delayed.

The Ultrapure Solution

Ultrapure water removes these interfering compounds to parts-per-billion levels. Total Organic Carbon (TOC) drops below 10 ppb. UV absorbance at 254 nm falls under 0.001 AU.

The result: Stable baselines. Consistent retention times. Reliable peak integration, identification and quantitation. Improved signal-to-noise ratios.

ICP-MS: Eliminating Spectral Interferences

The Elemental Challenge

Trace metals in water create spectral overlaps. Iron contamination interferes with chromium analysis. Calcium creates polyatomic interferences. Quantitation becomes systematically biased.

Technical mechanism: Even parts-per-billion metal contamination generates detectable signals. These signals overlap with your target isotopes. Mathematical corrections become unreliable when contamination varies between samples.

Laboratory impact: Your calibration curves become non-linear. Quality control samples fail acceptance criteria. Inter-element corrections introduce additional uncertainty. Your detection limits increase by orders of magnitude.

Precision Through Purity

Ultrapure water systems

remove metals to parts-per-trillion levels. Resistivity exceeds 18 MΩ·cm. Total metals content drops below 1 ppb.

The analytical advantage: Consistent blank values. Linear calibration curves across wider concentration ranges. Improved accuracy for trace element analysis. Lower detection limits for regulated contaminants.

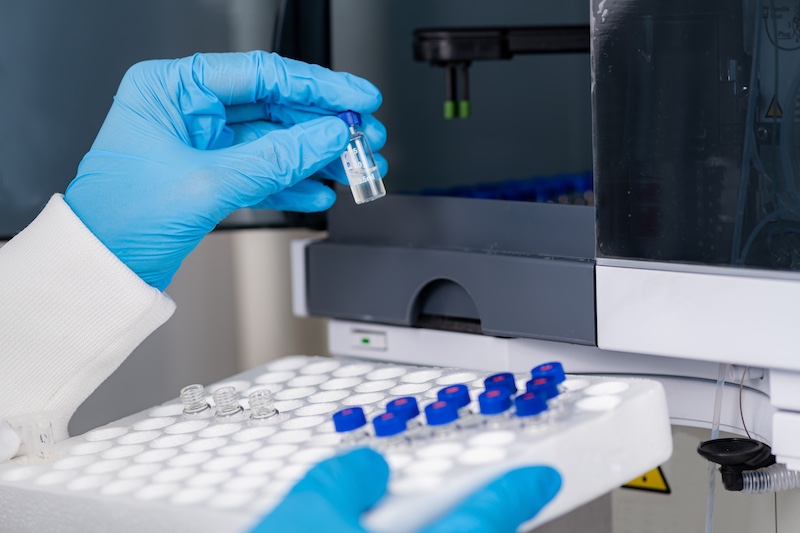

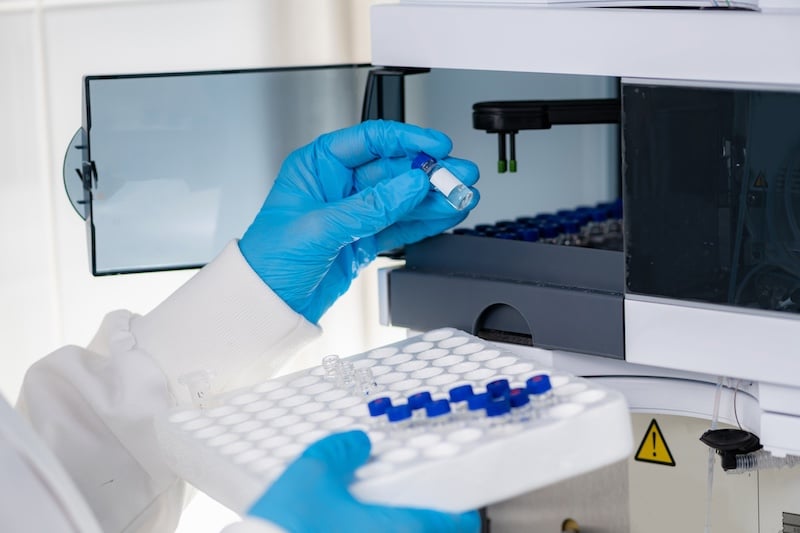

LC-MS: Optimizing Ionization Efficiency

The Ion Suppression Problem

Dissolved salts suppress electrospray ionization. Organic contaminants compete for charge. Your target compounds show reduced signal intensity. Peak areas become irreproducible.

Technical mechanism: Sodium and potassium adducts shift your molecular ion peaks. Surfactants from water treatment create ion suppression. Buffer salts precipitate in your ion source. Cleaning cycles become more frequent.

Operational consequences: Method sensitivity decreases. Matrix effects become unpredictable. Ion source maintenance increases. Instrument downtime rises.

Enhanced Ionization Through Water Purity

Ultrapure water eliminates ionic contamination. Conductivity drops below 0.1 μS/cm. Dissolved gases are removed to prevent oxidation artifacts.

Performance benefits: Consistent electrospray performance. Reduced ion source contamination. Improved peak shape and resolution. Extended maintenance intervals.

The Workflow Revolution

Before Ultrapure Water

After Implementation

Economic Impact Beyond the Lab

Regulatory compliance: Methods meet validation criteria on first attempt. Submissions proceed without analytical delays. Audit findings decrease significantly.

Operational efficiency: Instrument utilization increases. Maintenance costs decrease. Sample throughput improves. Staff productivity rises.

Data integrity: Results become more reliable. Inter-laboratory comparisons improve. Method transfer success rates increase. Regulatory confidence grows.

Frequently Asked Questions

Immediate benefits appear within hours. Your first blank injection will show reduced background noise. Baseline stability improves immediately. However, complete system equilibration may take 24-48 hours as residual contaminants flush from your HPLC lines and columns.

The most dramatic improvements occur within the first week as your entire analytical system reaches equilibrium with the ultrapure water supply.

One ultrapure water system serves multiple analytical needs. HPLC, ICP-MS, and LC-MS all benefit from the same water quality specifications: >18 MΩ·cm resistivity, <10 ppb TOC, and <1 ppb total metals.

The key is point-of-use delivery. Install dispensing points near each instrument to minimize recontamination from storage or transport.

Bottled water degrades during storage. Even sealed containers allow CO2 absorption, reducing resistivity. Organic leaching from plastic containers increases TOC levels over time.

Fresh ultrapure water maintains consistent quality. On-demand generation ensures optimal purity at the moment of use. No storage-related degradation occurs.

Run systematic comparisons using your existing methods. Analyze the same samples using your current water supply versus ultrapure water. Compare baseline noise, peak integration, and detection limits.

Key validation metrics include: Signal-to-noise ratio improvements, baseline stability over extended runs, and reduced frequency of "unknown" peaks in your chromatograms.

Modern systems require minimal daily attention. Replace consumables according to manufacturer schedules. Monitor water quality parameters continuously through built-in meters.

Critical maintenance tasks include: Resin bed replacement every 6-12 months, UV lamp replacement annually, and periodic system sanitization. Most systems provide automated alerts when service is needed.

Discover the CLïR lab water system best suited for your application.

Want to learn more about the ins and outs of water treatment? Subscribe to this blog and we'll keep you posted.

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.

Your HPLC columns shouldn't fail after a few weeks. Under normal operating conditions, most reverse-phased C18 columns deliver stable performance for...

Ultrapure water (UPW) is like a lab's clean room, but in liquid form. At 18 MΩ-cm resistivity, Type I water isn't just "really clean"—it's so pure...

Water contamination causes 60-70% of unexplained ghost peaks in LC-MS.

Your HPLC system is calibrated perfectly. Your columns are fresh. Your mobile phase is prepared with precision. Yet your results are inconsistent,...

Your LC-MS system is calibrated perfectly between your set up and check standards. Your columns are fresh. You are running validated methods. Yet...